Electrical and automation solutions tailored for the needs of various industrial fields

OT-Control Oy designs and produces customised electrical and automation solutions for numerous branches of industry. Our expertise is rooted in experience that spans more than three decades, which gives us the ability to meet our customers’ specific needs – no matter how challenging.

•

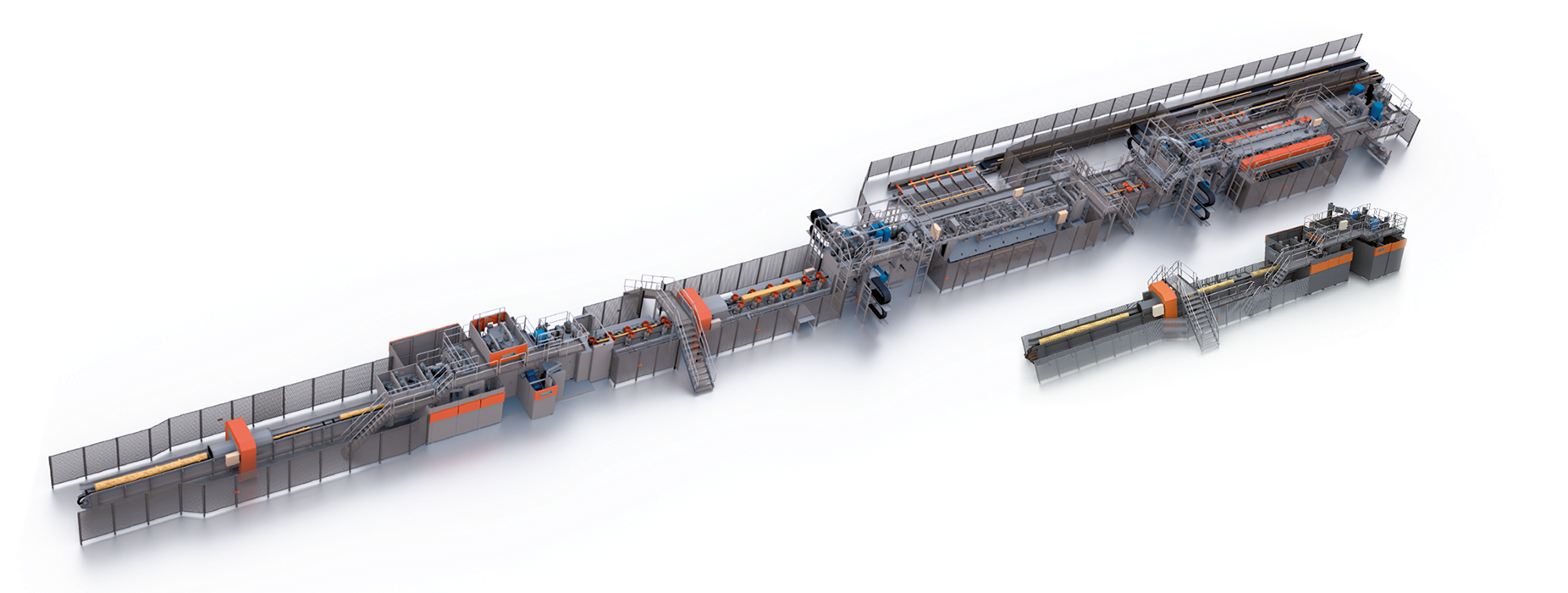

Our strongest expertise is in the realisation of automation projects for the wood-product and sawmill industries, with experience ranging from large-scale sawmill production lines to timber-dryers and from log-processing machines for construction to presses.

•

A broad base of knowledge and experience enables us to create innovative, comprehensive automation solutions for many other industries too. Our motto is ‘the more complicated the machine, the better we are’.

Automation projects for the wood-product and sawmill industries

Log processing

Sawing

Timber handling

Drying

Greater productivity and competitiveness

Our business philosophy is to boost our customers’ production capacity and productivity with top-notch automation solutions. Our design work is based on solutions that give our customers a competitive edge and meet the functional requirements for the system. OT-Control’s electrical and automation solutions help to raise your production processes to the next level.

•

Technological expertise

Programming of automation solutions represents our core expertise. Our design success stems from solid software architecture and high-quality coding that come together to form a reliable and cost-efficient basis for further development and easy maintenance. Our customers see the benefits of this work in the fast, efficient, and reliable performance of their systems.

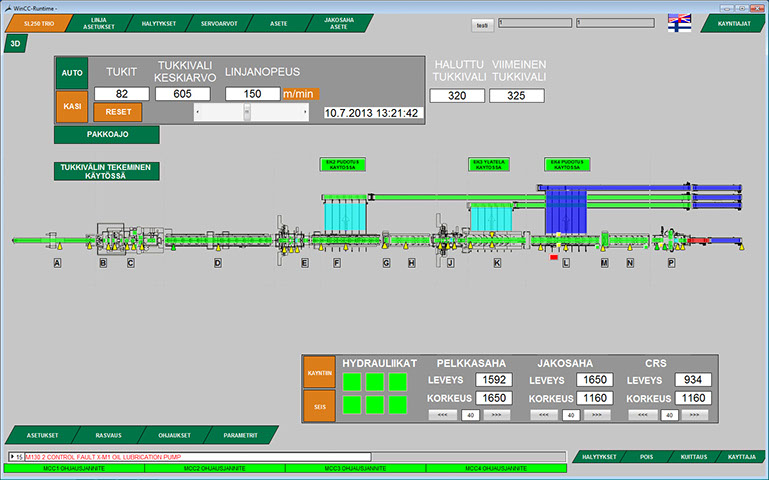

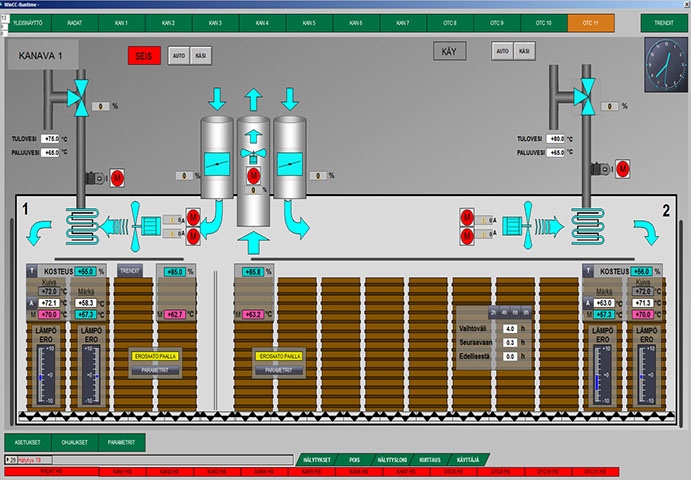

State-of-the-art interfaces

Our goal is to create positive user experiences by designing well-functioning, clear, and visually pleasing user interfaces. We aim to produce systems that are intuitive and logical to use, a feature that is particularly pivotal for complex devices and production lines. Our easy-to-use interfaces make the work more motivating and increase productivity.

A responsible partner for 24/7 operations

We aim to forge long-term partnerships by offering the best service in the field. Thanks to our 24/7 operations service, our customers can rely on our automation solutions to function without interruption. Our updating and modernisation services guarantee that our solutions enjoy a long service life and can be adapted to any changes in the requirements and circumstances.

Elimination of risk – we bear responsibility for the comprehensive automation solution

All too often, automation of production processes involves several separate systems, without any guarantee of their compatibility. This also makes it difficult to identify the cause of any problems that arise in the functioning. When our experts create a comprehensive automation solution for your production, we can control the efficiency and functioning of the production operations holistically.

•

We aim to forge long-term partnerships, which form part of our product life-cycle management philosophy. Our experts are available to assist you at all times with any problems you may encounter. Rapid troubleshooting ensures that production downtime is kept to a minimum.

Cutting-edge technology, creating new opportunities

With an integrated, state-of-the-art camera system, your production processes can be easily optimised. The use of cameras enables smoother, more efficient, and less error-prone production-line processes.

More efficient production

Higher capacity

More consistent production

Fewer defects and minimal losses

Better quality control

Enhanced traceability

Easier integration

A decrease in manual work

Faster deliveries

Better ergonomics

We come into our own in challenging automation projects

An innovative, efficient, and reliable partner

We are at your service as an innovative, efficient, and reliable partner. In addition to electrical and automation design, we excel in mechanical engineering. To ensure that we remain at the forefront of the production automation field, we keep abreast of the latest technological innovations. We always use state-of-the-art tools and software. Our close collaboration with companies such as Siemens and ABB guarantees that we are in the vanguard of developments in the fields of software and mechanical engineering. We are fully authorised to carry out electrical work and contracting. This helps to ensure the reliable functioning and timely delivery of our software.

•

Automation projects for the sawmill industry

• Sorting of logs

• Feeding of logs

• Log-cutting

• Processing of wood chips and sawdust

• Dimension-based sorting and timber trimming

• Drying

• Sorting and packing of dry timber

Automation projects for other industries

• Robotised operations

• Stone-working

• Fields that use presses / pressing lines

• The building industry (with log machinery)

• Fields that use concrete plants

• Fields that use batching plants

• Waste treatment

Needs analysis

• Analysis of the production process

• Identification of problems

• Analysis of development needs

• Assessment of end-product quality

Commissioning

• Automation testing, including an on-site test run of the solution before hand-over

User training and documentation

• Effective training before commissioning of the system

• An illustrative manual as part of the delivery

Extensions, updates, and modernisation

• Life-cycle management, a key part of solutions that are easy to update, extend, and adapt to changing circumstances

Remote operation

• Monitoring and maintaining of the solutions’ functioning and condition via a remote control system

Design

• Comprehensive technological solutions

• Robotics

• Electrical and automation design

• Close collaboration with the device supplier

Consulting services

• Innovations and product development for production processes

Optimisation

• The best possible automation solution to boost your competitiveness, productivity, and efficiency

Cutting-edge technology, creating new opportunities

With an integrated, state-of-the-art camera system, your production processes can be easily optimised. The use of cameras enables smoother, more efficient, and less error-prone production-line processes.

Versatile expertise in various fields

The sawmill industry

• Sorting of logs

• Feeding of logs

• Log-cutting

• Processing of wood chips and sawdust

• Dimension-based sorting and timber trimming

• Drying

• Sorting and packing of dry timber

Other sectors

• Robotised operations

• Stone-working

• Fields that use presses / pressing lines

• The building industry (with log machinery)

• Fields that use concrete plants

• Fields that use batching plants

• Waste treatment

Deliveries to numerous countries

Contact information

Project Sales, production and development

Jukka Pakarinen

Managing Director

Sales

+358 40 539 0722

jukka.pakarinen@ot-control.fi

Petri Pulkkinen

Managing Director

Production

+358 44 570 7183

petri.pulkkinen@ot-control.fi

Automation, ELECTRICAL and SOFTWARE design

Jukka Uotinen

Automation Project Manager

+358 400 716 321

jukka.uotinen@ot-control.fi

Ville Ahokas

Automation engineer

+358 44 493 2570

ville.ahokas@ot-control.fi

Pasi Turusenaho

Software engineer

+358 44 988 4301

pasi.turusenaho@ot-control.fi

Kimmo Koskinen

Automation engineer

+358 44 366 6975

kimmo.koskinen@ot-control.fi

Timo Riihikoski

Automation Project Manager

+358 40 844 8539

timo.riihikoski@ot-control.fi

Ville Paakki

Automation engineer

+358 44 099 0125

ville.paakki@ot-control.fi

Seppo Silvennoinen

Software engineer

+358 44 508 1524

seppo.silvennoinen@ot-control.fi

Jarkko Tuuva

Automation and Electrical engineer

+358 50 589 6772

jarkko.tuuva@ot-control.fi

Ismo Koivisto

Automation Project Manager

+358 400 277 741

ismo.koivisto@ot-control.fi

Piia Mattila

Design assistant

+358 44 730 0344

piia.mattila@ot-control.fi

Jani Tikkanen

Software engineer

+358 50 402 7239

jani.tikkanen@ot-control.fi

Electrical installation

Jukka Pääkkönen

Electrician

+358 44 741 9203

jukka.paakkonen@ot-control.fi

Jere Tuuri

Electrician

+358 40 532 2596

jere.tuuri@ot-control.fi

Otto Degerman

Electrician

+358 44 765 0440

otto.degerman@ot-control.fi

Administration

Jukka Pakarinen

Managing Director

+358 40 539 0722

jukka.pakarinen@ot-control.fi

Jukka Uotinen

Chairman of the Board

+358 400 716 321

jukka.uotinen@ot-control.fi

Our office

Hannele Toivanen

Office secretary

+358 44 705 1389

hannele.toivanen@ot-control.fi

Tiina Malmi

Payroll and Documentary

+358 44 775 8613

tiina.malmi@ot-control.fi

Suomi

Suomi Русский

Русский Svenska

Svenska